KF HEMP

Hemp

KF HEMP

Website: www.kfhemp.com

Project Location: Regina, Saskatchewan

Project Completion Date: April 2019

System Size: SPD-12000BB

Finished Product: Hemp

Building a Legacy of Pioneering New Industries.

Kambeitz Farms has emerged as a North American leader in agricultural production and innovation. It has grown to a 60,000 acre source of the world’s finest grains, oilseeds, pulses and hemp . Growing, feeding, protecting and nurturing crops is in their DNA.

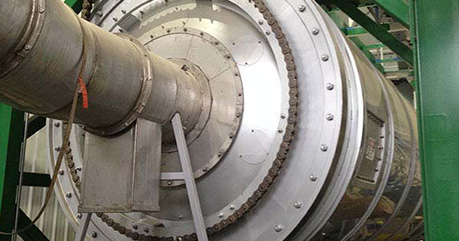

Uzelac Industries Drying System consists of a 30MM Btu/hr Burner supplied by Maxon, a Uzelac Industries Furnace, a Uzelac Industries single pass drum, 10’-9 1/2'” diameter X 48’ long, with a 250 HP Fan. Systems Controls designed and provided by Uzelac Industries are Allen Bradley Panel View PLC controls. The system is designed to process 10 ton per hour of hemp at 80% moisture content and dry them to 8% moisture content. The system is primarily stainless steel construction.

“The team at Uzelac Industries has been true professionals throughout the entire project. They were exceptional with their equipment and process knowledge during my procurement and evaluation stage. Mike Hobbs and Ken Koeslin had the great ability to simplify and articulate technical processes much better than their competitors which is ultimately why we selected Uzelac for our project. We were the first project for them with a hemp specific application and they had the foresight to modify the layout and capabilities of the equipment that they custom designed for our application, specifically with the conveyance challenges that we faced. They were able to adapt to some unique requests without hesitation and with strong confidence in changes because of their rich experience in the drying industry. The installation instructions were very comprehensive and easy to execute both mechanically and with the controls and electrical service. The Uzelac team was also very insightful regarding many of the support equipment for optimizing our drying process such has monitors, moisture balances, etc. The Uzelac team specifically, John Trzesniewski and JR Weber have been supportive and very accessible throughout the build out of the system through commissioning and continue to be as we’ve successfully and on schedule entered production operations. It became evident that Uzelac selects the best vendors and partners for the controls, burners and other hardware which has allow us to locally adapt and modify our process order to best fit our unique and changing process requirements. I would personally highly recommend using Uzelac Industries has a drying equipment vendor and partner, their true passion for the equipment and the drying industry has made them a leader in the industry and a true pleasure to work with.”

- Kris Heshka - Vice President of Operation

Build and Install for KF Hemp.

Drum Fabrication

Drum

Cyclone Shipment

Final Install

Final Install

Cyclones

Ductwork

Completed System

Completed System

Final Install

VIEW ADDITIONAL CASE STUDIES

See how we’ve helped other clients reach their goals.

Rotary Dryers

Many industries use rotary dryers to minimize moisture content in material during the manufacturing process. Typically, these systems use heated gas to dry material in a large rotary chamber.

Biomass

Biomass is organic material that comes from plants and animals and can be used for energy production. Although many substances such as agricultural crops and waste materials can be burned for fuel, the most common biomass used for fuel is wood and wood processing wastes.

Gasification

Gasification is a chemical reaction caused by heating material in an oxygen-starved environment, resulting in incomplete combustion that drives off carbon-rich gases. Gasification is a chemical reaction caused by heating material in an oxygen-starved environment, resulting in incomplete combustion that drives off carbon-rich gases.

READY TO LEARN MORE?

We would love to hear from you and answer any questions you might have.

You can email us at info@uzelacind.com

or Fill out the form and someone from our team will get back to you right away.

or You can give us a call at 414-529-0240.