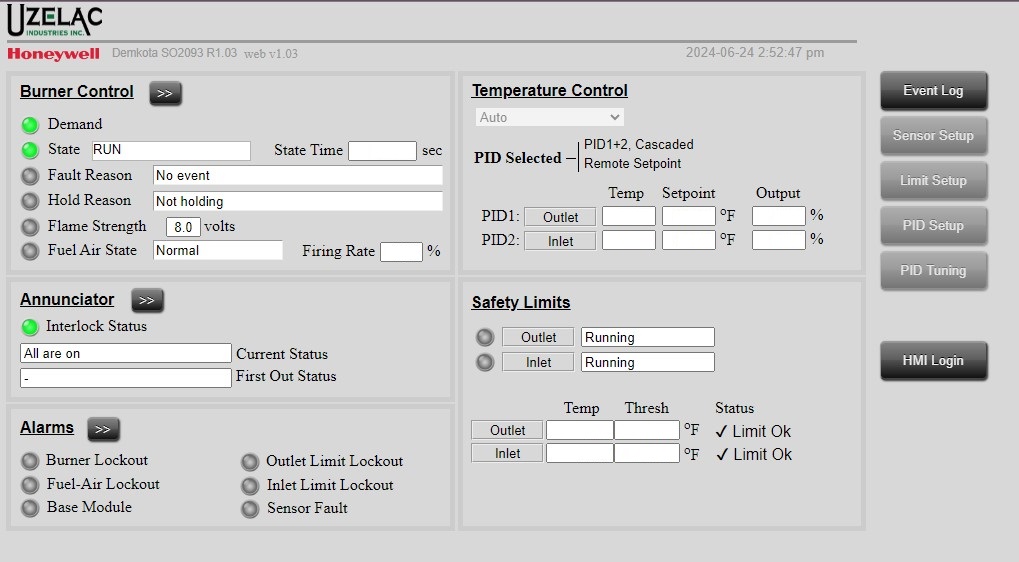

Uzelac Industries has now started using a new Honeywell Burner Control System called Slate.

The main reason this upgrade was made is the benefit of remote support that the Slate System offers. Recently, our customers at DemKota Ranch Beef were having issues that we were able to troubleshoot remotely and get them back up and running that same day, saving them days of lost production and income.

What happened onsite: The HMI onsite was soaked with water and the screen went out. They were not able to make any changes to the system or see the settings, so the system was down and they were unable to run product. They called Uzelac Industries for assistance.

How the issue was resolved: When the customer called in, a Uzelac Industries team member connected into the panel using a cellular Ixon connection. We were able to control both the Slate System and the Allen-Bradley PLC on our end and set parameters so we could keep the system running while the customer was waiting on a new HMI. A technician connected the next morning to start the system again and download the backup when the new HMI arrived.

By using the remote troubleshooting capabilities of the Slate system, DemKota was only down for a few hours instead of a few days. Currently DemKota is running 4 tons an hour of blood at an estimated price per ton of $1,000, so they saved tens of thousands of dollars by having the Slate Burner Control System.

‟Working with the Uzelac team was very smooth. They were able to assist right away when I called. They walked me through what to check on the system and we were able to get the issue resolved much quicker than if I did not have their remote assistance.ˮ

Lane Holt- DemKota Ranch Beef