Application of Uzelac Manure Drying Systems

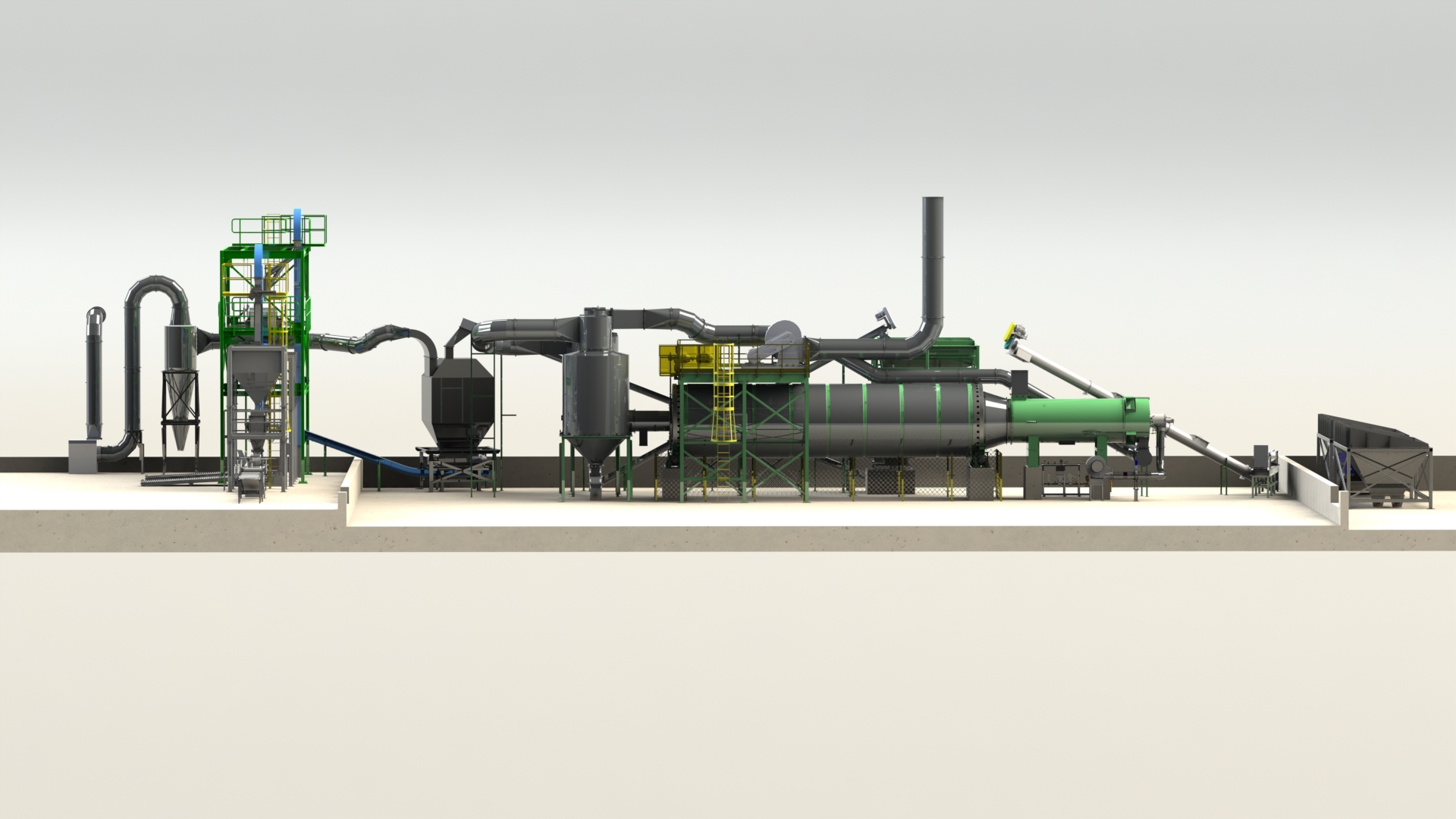

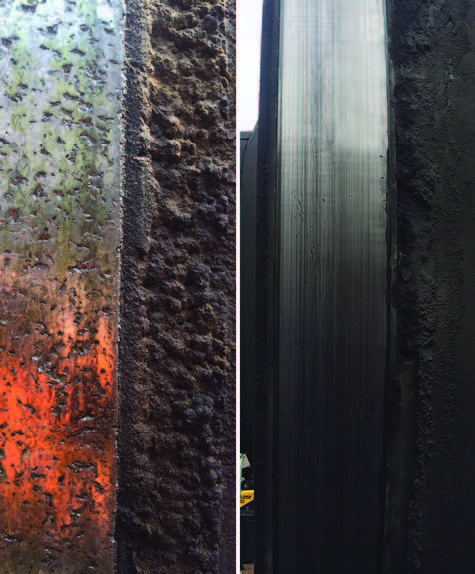

Uzelac Industries based in Greendale, WI. has developed considerable expertise in the design and installation of rotary drum dryers capable of reducing the moisture content of manure from high-rise houses with 65 percent water or belt systems with 45 percent water down to 15 percent. Manure handling and drying installations convert a waste product into a valuable pathogen-free fertilizer in a commercially acceptable form for domestic and institutional applications.

Direct application of raw manure to farmland will be subject to increasing restriction as nitrogen percolating through soil contaminates ground water and hence wells. Runoff entering streams and waterways will come under heightened scrutiny from state and federal regulators.

A Uzelac rotary dryer installations reduces odor, obviating complaints and lawsuits and when used with belt manure collection, effectively eliminates fly problems without expenditure on insecticides. In the future environmental regulations may necessitate on-farm or remote processing of manure before application.

Read the rest of this article Written by Dr. Simon M. Shane on Egg-News.com