TRACK / TIRE RESURFACING AND REPLACEMENT FOR M-E-C DRYER DRUMS

Uzelac Industries |Nov. 3rd, 2020

TRACK / TIRE RESURFACING AND REPLACEMENT

Make sure to get on our maintenance schedule to minimize any possible downtime!

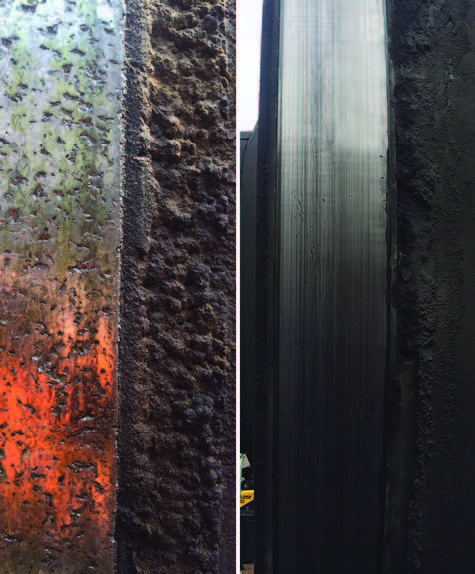

TRACK RESURFACING

We have the experience and equipment to resurface M-E-C drum track / tires, safely and efficiently, minimizing downtime.

Resurfacing track / tires creates a flat level surface:

• Eliminates pitting and prevents cracking

• Eliminates vibration by reducing ripples in

track / tires

Resulting in:

• Prolonged life of bearings, trunnions, thrust

rollers and the track / tires itself

• Improved dryer tracking performance

Reduced trunnion adjustment

REPLACING END TRACK/TIRES

Uzelac Industries has the ability to replace track / tires located in the end of your dryer drum using well-established and proven methods.

REPLACING IN-BOARD TRACK / TIRES

We offer an alternative technology to replace in-board tracks that will reduce down time

during replacement by over 50%. We completely eliminate the need to cut-off the end of the drum to replace the track / tires.

CASE STUDY

We replaced the in-board track on a 12’ x 72’ M-E-C drum for a customer in Dallas. This drum has been running for over 3 years without any issue. Our technology saved the facility over 130 hours of downtime, compared to the traditional process.